Analog circuits rely on both active and passive components to function efficiently. While transistors play a crucial role, passive components such as capacitors and resistors are equally essential. These components influence signal processing, filtering, and stability in analog designs. In this blog, we’ll explore the role of capacitors and resistors in analog circuits, focusing on their types, functions, and significance in MOS (Metal-Oxide-Semiconductor) technology.

Capacitors in Analog Circuits

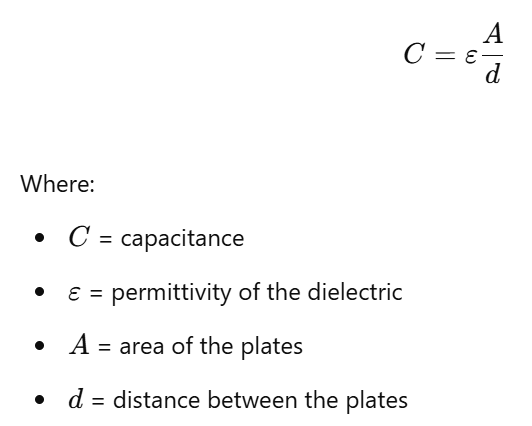

A capacitor is a two-terminal passive component that stores and releases electrical energy. It consists of two conductive plates separated by a dielectric material. The capacitance (μF, nF, pF) is determined by:

Role of Capacitors in Analog Circuits

- Filtering: Used in low-pass and high-pass filters to remove unwanted frequencies.

- Coupling and Decoupling: Block DC components while allowing AC signals to pass.

- Charge Storage: Store and release energy in power circuits.

- Stability Enhancement: Improve circuit performance by stabilizing voltage levels.

Characteristics of a good capacitor:

- Capacitor matching is crucial for differential circuits and precision analog applications.

- Show minimal change in capacitance with voltage

- Have a high capacitance per unit area

- Low-temperature coefficient capacitors ensure stable operation in varying environmental conditions.

Types of Capacitors Used in CMOS Circuits

1] MiM (Metal-Insulator-Metal) Capacitors

- Built using metal layers with a thin insulating layer in between.

- Common in modern submicron processes (like 0.18μm).

- High accuracy and minimal unwanted capacitance.

- Used in circuits that require precision.

2] MOS Capacitors (Accumulation Mode Capacitors)

- Uses an n-well as the bottom plate and n+ diffusion or polysilicon as the top plate.

- Offers higher capacitance per unit area but is not as precise as MiM capacitors.

- Used when one terminal is connected to ground.

3] MOM (Metal-Oxide-Metal) Capacitors

- Made using existing metal layers in digital CMOS processes.

- Lower capacitance per unit area compared to MiM capacitors.

- More efficient for RF circuits because they have lower energy loss.

Parasitic capacitance is the unwanted or unintended capacitance that exists between different parts of an electronic circuit due to their physical proximity. In Analog Circuits, it can cause signal distortion, unwanted phase shifts, and reduced circuit performance.

Resistors in Analog Circuits

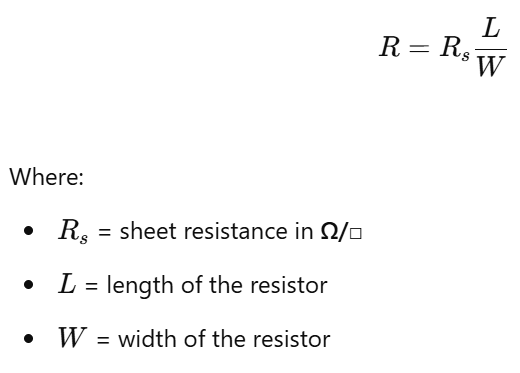

A resistor is a passive component that opposes the flow of electrical current. Resistors are fundamental in MOS technology, even though circuits primarily use active devices and capacitors. Their resistance is determined by:

Role of Resistors in Analog Circuits

- Voltage Division: Used in divider circuits to obtain specific voltage levels.

- Current Limiting: Control current flow in various circuit sections.

- Pull-Up and Pull-Down Functions: Ensure logic stability in digital circuits.

- Biasing Components: Maintain correct operating points in transistors and amplifiers.

Types of Resistors in MOS Technology

- Diffused Resistors — Created using the same diffusion process as transistors’ source and drain regions.

- Polysilicon Resistors — Made from a thin layer of polysilicon, commonly used due to their stability.

- N-Well Resistors — Formed in an n-well region of a chip and have high resistance.

- Metal Resistors — Less common but can be used in some cases.

Sheet Resistance and Its Role

Since the thickness of the resistor material is generally fixed, resistance calculations use sheet resistance (Ω/□). The formula simplifies to:

Capacitors and resistors are vital passive components in analog circuits. Capacitors store and regulate charge, while resistors control current flow and define circuit behavior. In MOS technology, different types of capacitors and resistors provide specific advantages, influencing circuit efficiency and performance. Understanding their properties and applications is key to designing optimized analog circuits.

Do you have questions or insights on using passive components in analog design? Share your thoughts in the comments! 🚀