Check out the extensive list of topics we discuss:

- Tech and AI Blogs

- Communication Protocols:

- USB

- RS232

- Ethernet

- AMBA Protocol: APB, AHB and ASB

- UART, I2C AND SPI - Important concepts in VLSI:

- Designing a Chip? Here Are the 12 Important Concepts You Need to Know

- Metastability

- Setup time and Hold time

- Signal Integrity and Crosstalk effect

- Skews and Slack

- Antenna Effect - Semiconductor Memories

- Analog vs Digital Electronics

- Most Frequently Asked Questions in VLSI

- VLSI and Semiconductor Nuggets: Bite-Sized knowledge for Enthusiasts

- Common Acronyms in VLSI and Semiconductor Industry

- Transistors:

- BJT

- JFET

- MOSFET

- CMOS

- Transmission Gate CMOS

- Dynamic CMOS - Sequential Circuits:

- Registers

- Counters

- Latches

- Flip Flops - FPGA:

- ASIC vs FPGA

- FPGA Insights: From Concept to Configuration

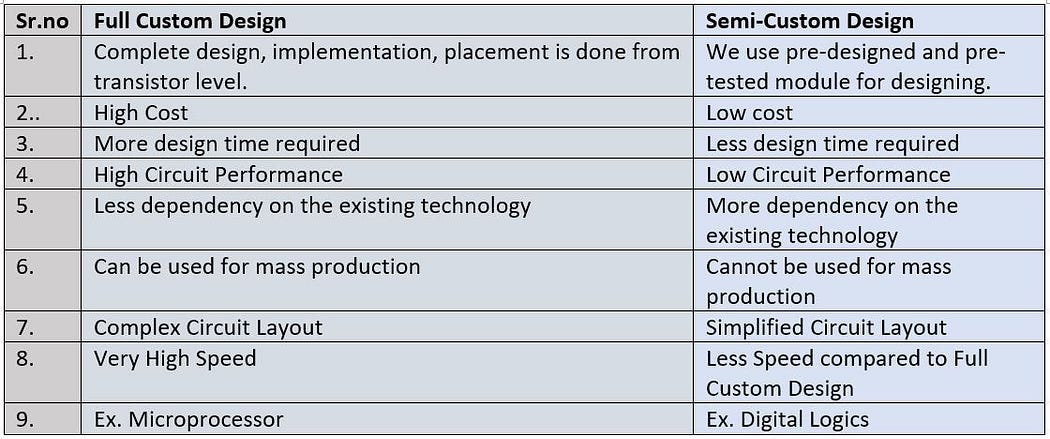

- Full-Custom and Semi-Custom VLSI Designs: Pros, Cons and differences

- From Theory to Practice: CMOS Logic Circuit Design Rules Made Easy with Examples - CMOS Fabrication:

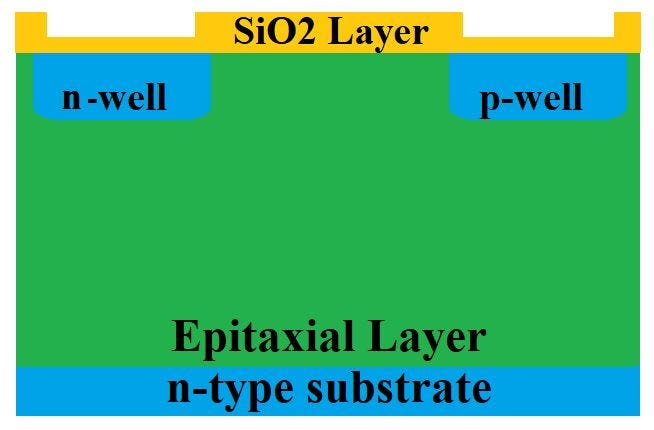

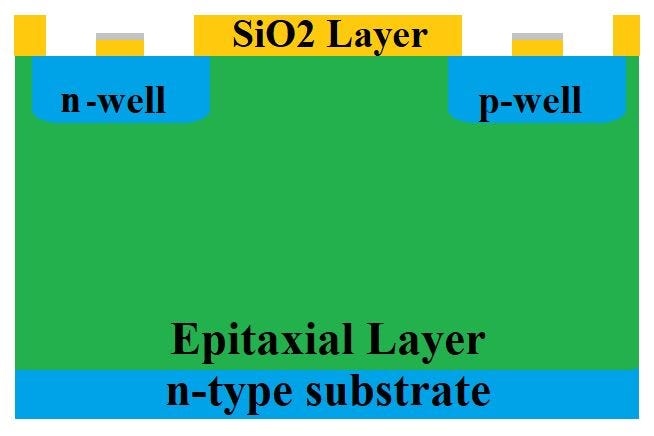

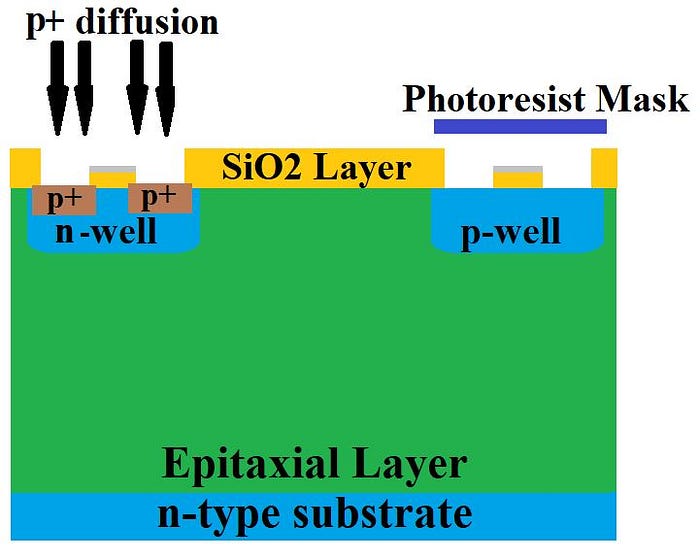

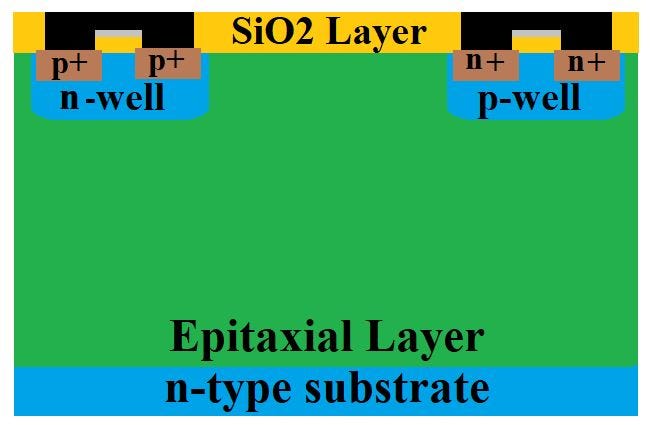

- CMOS Fabrication

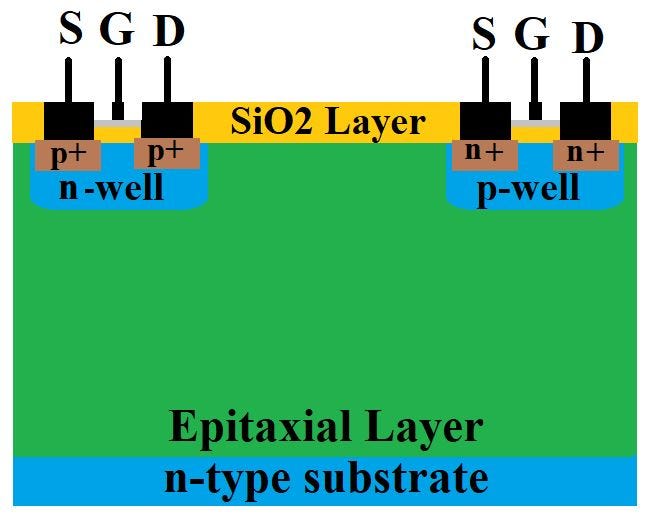

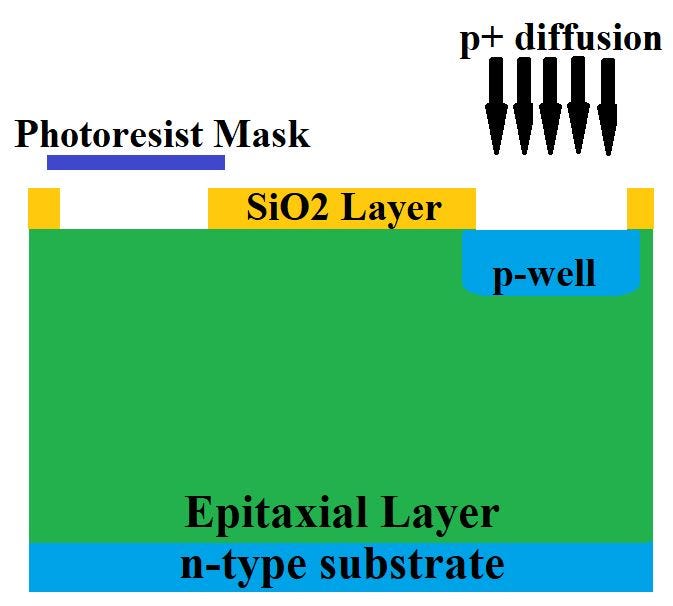

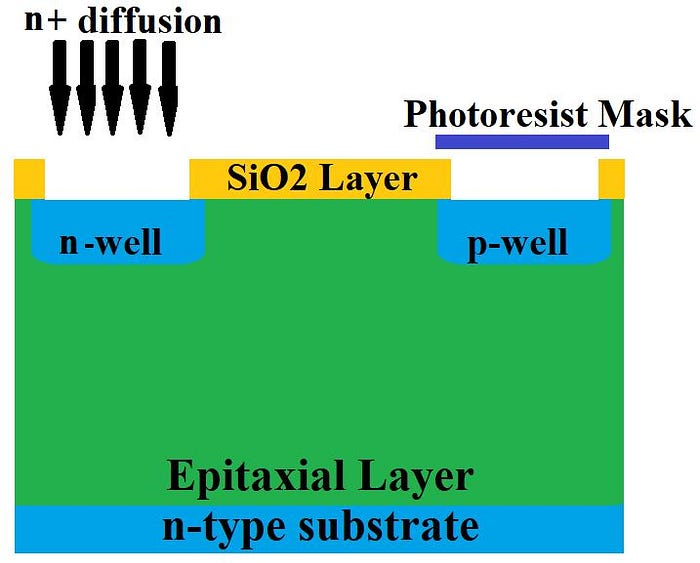

- Twin-Tub CMOS Technology - Combinational Circuits

- Logic Gates

- Boolean Algebra and DeMorgan's Law

- Multiplexer (MUX) and Demultiplexer (DEMUX)

- Half Adder

- Full Adder

- Half Subtractor

- Full Subtractor

- Encoders

- Decoder - Analog Electronics

- OPAMP

- Inverting and Non-inverting Amplifiers

- Characteristics of OPAMP

- OPAMP Application: Adder, Subtractor, Differentiator, and More!

- Filters

- Hard Disk Drives Explained

- Passive Components: Capacitors and Resistors Explained

- LTSpice Tutorial 1: Installation and First Circuit Simulation - Verilog

- Verilog Datatypes

- Comments, Numeral Formats and Operators

- Modules and Ports

- assign, always and initial keywords

- Blocking and Non-Blocking Assignments

- Conditional Statements

- Looping Statements

- break and continue Statement

- Tasks and Functions

- Parameter and generate

- Verilog Codes - System Verilog:

- Disable fork and Wait fork.

- Fork and Join. - Project on Intel Quartus Prime and Modelsim:

- Vending Machine Controller - Xilinx Vivado Projects

1)VHDL

- Counters using Testbench code

- Flip Flops using Testbench code

- Logic Gates using Testbench code

- Full Adder using Half Adder and Testbench code

- Half Adder using Testbench code

2)Verilog

- Logic Gates using Testbench code

- Counters using Testbench code

- Full Adder using Half Adder and Testbench code

- Half Adder using Testbench code - VLSI Design Flow:

- Design Flow in VLSI

- Y chart or Gajski Kuhn Chart - Projects on esim:

- Step-by-Step guide on how to Design and Implement a Full Adder using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a Half Adder using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a 2:1 MUX using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a Mixed-Signal Circuit of 2:1 Multiplexer - IoT based project:

- Arduino

- Step-by-Step guide on how to Interface Load Cell using Arduino - Kmaps:

- Simplifying Boolean Equations with Karnaugh Maps - Part:2 Implicants, Prime Implicants and Essential Prime Implicants.

- Simplifying Boolean Equations with Karnaugh Maps - Part:1 Grouping Rules.

- Simplifying Boolean Equation with Karnaugh Maps.

- USB

- RS232

- Ethernet

- AMBA Protocol: APB, AHB and ASB

- UART, I2C AND SPI

- Designing a Chip? Here Are the 12 Important Concepts You Need to Know

- Metastability

- Setup time and Hold time

- Signal Integrity and Crosstalk effect

- Skews and Slack

- Antenna Effect

- BJT

- JFET

- MOSFET

- CMOS

- Transmission Gate CMOS

- Dynamic CMOS

- Registers

- Counters

- Latches

- Flip Flops

- ASIC vs FPGA

- FPGA Insights: From Concept to Configuration

- Full-Custom and Semi-Custom VLSI Designs: Pros, Cons and differences

- From Theory to Practice: CMOS Logic Circuit Design Rules Made Easy with Examples

- CMOS Fabrication

- Twin-Tub CMOS Technology

- Logic Gates

- Boolean Algebra and DeMorgan's Law

- Multiplexer (MUX) and Demultiplexer (DEMUX)

- Half Adder

- Full Adder

- Half Subtractor

- Full Subtractor

- Encoders

- Decoder

- OPAMP

- Inverting and Non-inverting Amplifiers

- Characteristics of OPAMP

- OPAMP Application: Adder, Subtractor, Differentiator, and More!

- Filters

- Hard Disk Drives Explained

- Passive Components: Capacitors and Resistors Explained

- LTSpice Tutorial 1: Installation and First Circuit Simulation

- Verilog Datatypes

- Comments, Numeral Formats and Operators

- Modules and Ports

- assign, always and initial keywords

- Blocking and Non-Blocking Assignments

- Conditional Statements

- Looping Statements

- break and continue Statement

- Tasks and Functions

- Parameter and generate

- Verilog Codes

- Disable fork and Wait fork.

- Fork and Join.

- Vending Machine Controller

1)VHDL

- Counters using Testbench code

- Flip Flops using Testbench code

- Logic Gates using Testbench code

- Full Adder using Half Adder and Testbench code

- Half Adder using Testbench code

2)Verilog

- Logic Gates using Testbench code

- Counters using Testbench code

- Full Adder using Half Adder and Testbench code

- Half Adder using Testbench code

- Design Flow in VLSI

- Y chart or Gajski Kuhn Chart

- Step-by-Step guide on how to Design and Implement a Full Adder using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a Half Adder using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a 2:1 MUX using CMOS and sky130nm PDK

- Step-by-Step guide on how to Design and Implement a Mixed-Signal Circuit of 2:1 Multiplexer

- Arduino

- Step-by-Step guide on how to Interface Load Cell using Arduino

- Simplifying Boolean Equations with Karnaugh Maps - Part:2 Implicants, Prime Implicants and Essential Prime Implicants.

- Simplifying Boolean Equations with Karnaugh Maps - Part:1 Grouping Rules.

- Simplifying Boolean Equation with Karnaugh Maps.