Welcome to our exploration of VLSI (Very Large Scale Integration) design methodologies. In the realm of VLSI, designers have two primary approaches: Full Custom Design and Semi-Custom Design. Each has its strengths and weaknesses, catering to different project requirements and constraints.

1] Full Custom Design: Full Custom Design involves creating and verifying all components of a chip from the transistor level upward. This meticulous process allows for precise optimization of speed, power, and area, making it ideal for mass production. However, it comes with a trade-off — the design and production time of full custom designs are typically longer compared to semi-custom designs.

- Advantages of Full Custom Design:

- Optimized performance: Full custom designs can achieve higher performance levels compared to semi-custom designs.

- Area efficiency: By tailoring every component, full custom designs can minimize chip area.

- Power optimization: Fine-grained control over individual components enables power optimization.

- Disadvantages of Full Custom Design:

- Longer design and production time: Designing and verifying each component from scratch can be time-consuming.

- Not cost-efficient for small-scale projects: The high upfront investment in design and fabrication makes full custom design less suitable for low-volume productions.

2] Semi Custom Design: Semi-Custom Design offers a compromise between design flexibility and time-to-market constraints. In this methodology, pre-designed and pre-tested modules are used, with the option to customize and add additional components as needed. While it reduces design time, it may not be as optimized or cost-efficient for mass production compared to full custom design.

- Advantages of Semi-Custom Design:

- Reduced design time: Leveraging pre-designed modules accelerates the design process.

- Flexibility: Additional components can be integrated to meet specific requirements without starting from scratch.

- Suitable for low-volume productions: Semi-custom design offers a balance between customization and cost-effectiveness for smaller-scale projects.

- Disadvantages of Semi-Custom Design:

- Limited optimization: Pre-designed modules may not offer the same level of performance optimization as full custom designs.

- Higher production time: Despite faster design time, integrating and customizing modules can extend the overall production time.

- Performance analysis of design methodology w.r.t design time:

From the above graph we can conclude following points:

- Initial circuit performance of the full custom design is less as compared to semi-custom design as we design it from the basic transistor level.

- Semi-custom has design less time compared to full custom design to get a stable circuit performance.

- Circuit performance of the full custom design is higher than the semi-custom design.

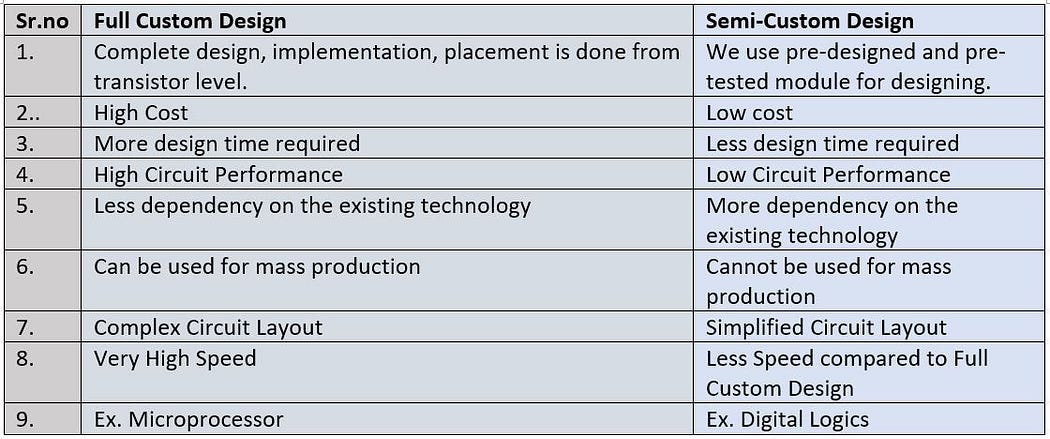

- Comparison between Full Custom and Semi-Custom design:

- Classification of Semi-Custom Design:

1] Standard Cell Design:

- The above diagram shows standard cells semi-custom design.

- Standard cells particularly use standard cell libraries which typically contain a few thousand cells, including inverters, Logic Gates, Adder circuits, Flip flops, AOI/OAI, etc.

- Each gate in this library will have its driving capabilities and parameters based on which we decide which block to be used.

- These standard cells have interconnects between them to perform different functions.

- The masking cost of standard cells is high.

- These cells can be used for both analog and digital designs.

- We don't perform floorplanning in a standard cell as blocks are already placed.

- Examples: Mux, Demux, Flip Flops, Logic Gates, Inverter, Adders, etc.

2] Gate Array Design:

- The above diagram shows the structure of the Gate Array.

- Here, the position of logic blocks is fixed.

- These logic blocks can be connected using interconnection wires to perform different functions.

- Structure also has I/O ports for interfacing.

- Here we program wires and via to implement the desired functions.

- In the gate array, the logic blocks are already placed in pre-defined positions but not connected to each other.

- These gate arrays reduce making costs and also reduce design time.

- As the size, no of logic blocks, transistors are fixed efficiency is less.

3] Programmable Logic Devices:

- These are the IC that can be programmed according to the required specifications.

- Some PLDs are :

1] SPLD (Simple Programmable Logic Devices)

2] CPLD (Complex Programmable Logic Devices)

3] FPGA (Field Programmable Logic Devices) - Comparison between different Design styles:

In conclusion, both full custom and semi-custom design methodologies play crucial roles in VLSI design. While full custom design offers unparalleled optimization and performance, semi-custom design provides flexibility and faster time-to-market for smaller-scale projects. Understanding the strengths and weaknesses of each approach is essential for selecting the most suitable methodology based on project requirements and constraints.

No comments:

Post a Comment